Name of Index | Specification | Packing Method |

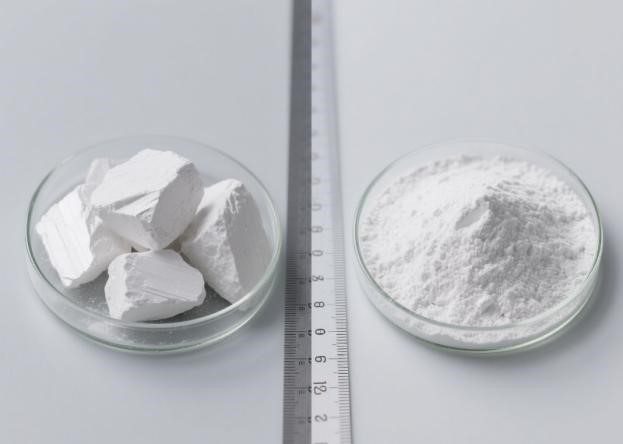

Appearance | White crystals or Powder | 1MT Jumbo ton bag packages; 25kg、50kgsmall package; customized packaging.

|

(Al2O3) Alumina | ≥99.2%

| |

(Na2O) Sodium oxide | ≤0.35%

| |

(SiO2) Silicon oxide | ≤0.1%

| |

Bulk density | ≥3.5g/cm3

| |

porosity | ≤5.0%

|

Grain Size Distribution Table

Specification(mm) | Sieve Mesh | Typical value of Particle composition(%) | Min-Max(%) |

5-3mm | |||

+5 | 5 | 5 | 0-10 |

+4 | 7 | 40 | |

+2.8 | 10 | 42 | |

-2.0 | 1 | 1-2 | |

3-1mm | |||

+3.35 | 6 | 3 | 1-5 |

+2.0 | 10 | 42 | |

-1.0 | 18 | 4 | 0-10 |

1-0mm | |||

+1.0 | 18 | 3 | 0-6 |

+0.5 | 35 | 46 | |

-0.102 | 150 | 18 | 10-25 |

1-0.5mm | |||

+1.4 | 14 | 1 | 0-3 |

+1.0 | 18 | 5 | |

+0.71 | 25 | 40 | |

-0.5 | 35 | 6 | 0-10 |

0.5-0mm | |||

+0.6 | 30 | 1 | 0-2 |

+0.5 | 35 | 4 | |

+0.25 | 60 | 55 | |

-0.045 | 325 | 11 | 5-20 |

0.045-0mm | |||

+0.075 | 200 | 0 | 0-3 |

-0.045 | 325 | 95 | 90-100 |

Tabular alumina is a high-purity, high-density alumina product processed through a specialized sintering process.

It has exceptional thermal stability and resistance to thermal shock.

With an extremely low coefficient of thermal expansion, excellent high-temperature performance, and corrosion resistance,

it is widely used in metallurgy, ceramics, electrical, and refractory material industries.

Tabular alumina is commonly used in high-temperature applications, such as furnace linings, sintered ceramics, and heating elements.

High-Performance Refractory Materials

· Shaped Products: Blast furnace iron trough bricks, sliding plate bricks, permeable bricks, steel ladle seat bricks, etc.

· Unshaped Materials: Low cement castables, self-flowing castables, dry spray materials, spraying materials.

· Features: Anti-corrosion, abrasion resistance, superior thermal shock stability, strong volumetric stability.

Ceramics and Functional Materials

· Applied in high-strength ceramics, electronic ceramics, and electrical insulating ceramics.

· Can improve ceramic strength, density, and wear resistance.

Metallurgy and Steel Industry

· Lining materials for steel ladles, molten iron ladles, and intermediate ladles.

· Increases service life, reduces energy consumption, and lowers maintenance costs.

Petrochemical and High-Temperature Kilns

·

· Refractory structures for critical parts of petrochemical cracking furnaces, gasification furnaces, etc.

· High-temperature stability, resistant to rapid cooling and heating.

Performance:

· Ultra-High Temperature Sintering: Achieved through high-temperature sintering at 1800-1900°C, resulting in materials with exceptionally high density and purity.

· Strong Thermal Shock Stability: Effectively resists thermal shock in high-temperature environments.

· High Mechanical Strength: Offers high strength and wear resistance, making it particularly suitable for demanding industrial conditions.

· Superior Insulation Properties: Exhibits excellent electrical insulation performance, ideal for use in the electronics field.