Specification | Particle size range | Chemical composition | Al₂O₃ | Specific gravity (g/cm³) | Porosity rate | Compressive strength (MPa) |

Bubble Alumina | 1–3mm | ≥98% Al₂O₃ | ≥98% | 1.30–1.40 | 50–65% | ≥200 |

Ultra-fine Bubble Alumina | 0.1–1mm | ≥99% Al₂O₃ | ≥99% | 1.35–1.45 | 60–70% | ≥250 |

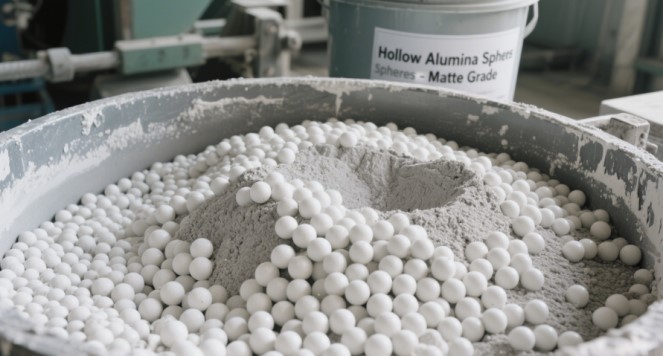

Bubble alumina Spheres are advanced lightweight materials made from high-quality bauxite.

They possess low density, high strength, and excellent resistance to high temperatures and chemical corrosion.

Their hollow structure gives them unique advantages, such as good thermal insulation and a larger specific surface area, making them ideal for use in refractory materials and adsorbents.

Bubble alumina are produced using precise sintering techniques, resulting in a uniform and stable structure.

Depending on the specific application requirements, these spheres can be produced in various sizes and compositions to meet the needs of different industries.

Applications:

l Lightweight Aggregate: Used in high-temperature furnace linings and refractory insulation materials,

as well as in the production of lightweight concrete and refractory bricks,

especially in the construction materials and high-temperature industries.

l Adsorbent: Used in chemical engineering as an adsorbent or catalyst carrier.

l Construction Industry: Used as insulation material, lightweight concrete, etc

.

l Oil & Gas Industry: Used for adsorption and filtration in oil extraction and natural gas refining processes.

Performance:

l Lightweight: Due to its hollow structure, it has a lower density, making it suitable for applications that require weight reduction.

l Good Thermal Insulation: The hollow structure provides excellent thermal insulation, effectively retaining heat or preventing heat transfer.

l High-Temperature Resistance: It has good high-temperature resistance, making it suitable for high-temperature environments.

l Chemical Stability: It has strong resistance to acid and alkali corrosion, making it suitable for use in various harsh environments.