![]() 2025-08-25

2025-08-25

![]() 小编

小编

White Fused Alumina (WFA) is an artificial abrasive and functional material made from high-purity alumina (Al₂O₃) as the core raw material, through high-temperature melting at over 2000℃, cooling crystal, crushing, and classification. Its Al₂O₃ content is generally above 99%, with a maximum of 99.8%, making it the artificial corundum variety with the highest purity currently available.

1. Physical Characteristics

The two major advantages of WFA are not accidental but stem from its unique physical structure and properties:

- Hard “Core” Hardness: Mohs hardness reaches Grade 9 (second only to diamond), with Vickers hardness ranging from 1800 to 2200HV—far exceeding ordinary metals and stones, laying the foundation for wear resistance.

- High-Temperature “Durable” Performance: Melting point is as high as 2050℃, with a long-term service temperature of 1900℃ and short-term tolerance to temperatures above 2100℃. Its linear expansion coefficient is only 7.5×10⁻⁶/℃ (20-1000℃), much lower than that of ordinary refractory bricks, ensuring it is not prone to cracking or deformation at high temperatures.

2. Different sizes in Refractory & Abrasive

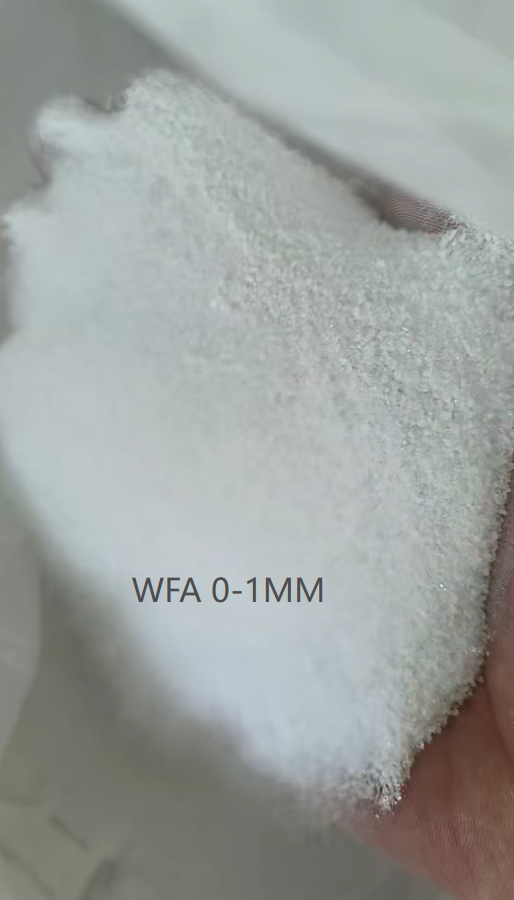

0-1mm: “Dense Filler” for Refractory Materials.

WFA particles of 0-1mm are fine with a large specific surface area (approximately 1-3m²/g). In refractory materials, they mainly play the role of “dense filling”, filling gaps between larger particles to improve the overall density and erosion resistance of the material.

0-1mm: “Fine Polishing Agent” for Precision Grinding.

WFA particles of 0-1mm are fine and uniform, with mild and uniform cutting force during grinding. They are suitable for precision polishing scenarios pursuing “high surface finish”.

1-3mm: “Structural Support” for Refractory Components

WFA particles of 1-3mm have a moderate size, combining strength and fillability. They are the core aggregate of refractory bricks and castables, playing the role of “structural support”.

1-3mm: “Main Cutting Agent” for Efficient Grinding

WFA particles of 1-3mm have moderate cutting force and low wear rate (0.5%-1.0%), making them the “main particles” for abrasive manufacturing, balancing efficiency and surface quality.

3-5mm: “Impact-Resistant Skeleton” for High-Temperature Equipment

WFA particles of 3-5mm have a larger particle size and high mechanical strength (compressive strength ≥30MPa), making them suitable for scenarios bearing high-temperature impact and gravity loads, serving as the “skeleton” of refractory materials.

3-5mm: “Impact-Resistant Aggregate” for Heavy-Duty Wear Resistance.

WFA particles of 3-5mm have a large particle size and high compressive strength, making them suitable for scenarios bearing heavy wear and impact, serving as the "wear-resistant skeleton" of wear-resistant materials.

3. Synergistic Advantages: Size Adaptation + Dual Properties, “Irreplaceable” in Cross-Border Scenarios

In some cross-border scenarios that need to cope with both “high temperature” and “wear” simultaneously, size-specific WFA can exert greater synergistic advantage, for example:

- High-Temperature Wear-Resistant Pipes (400-600℃)

- Waste Incinerator Liners (above 1000℃)

- Continuous Casting Rollers (1200℃)

To sum up, White Fused Alumina (WFA), with a core advantage of Al₂O₃ content ≥99% (up to 99.8%), is manufactured through processes including high-temperature melting at over 2000℃. It boasts robust physical properties refractory and abrasive. From high-temperature pipes to waste incinerator liners, WFA provides reliable material support for industrial upgrading across sectors, leveraging size adaptability and dual properties.